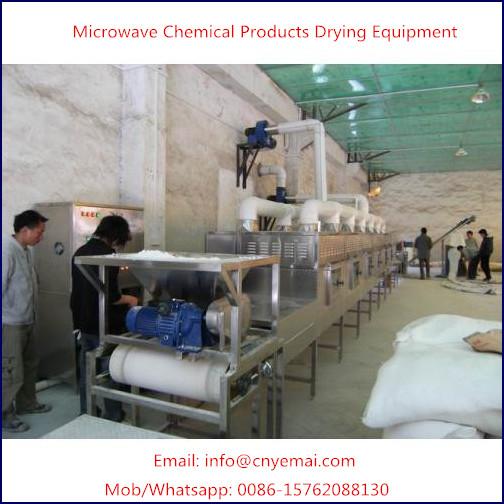

Model No.︰YM-80

Brand Name︰YM

Country of Origin︰China

Unit Price︰US $ 45000 / SET

Minimum Order︰1 SET

Application:

The equipments are used for the rapid desiccation of power ,granular,pasty materials,such as Glass fiber, battery material ,chemical raw materials, cellulose (eg hydroxyethyl cellulose, carboxymethyl cellulose, etc.), mannitol, nickel hydroxide, lithium cobalt oxide, graphite, carbon brushes, silicon carbide, calcium chloride dihydrate, activecarbon, zirconium oxychloride, zirconium oxide, copper oxide, aluminum oxide, zirconium hydroxide, zirconium carbonate, copper carbonate, manganese carbonate, is zirconium sulfate, ammonium zirconium carbonate, zirconium silicate, zirconium potassium carbonate, oil-based ink drying agentcross-linked anti-agent, water-based ink, expandable graphite, a variety of ceramic zirconium oxide, iron oxide, cobalt oxalate etc.Water content from 40% to 0.5% after drying ,drying time only need 5~6 minutes,temperature can be controlled in 0~200celsius degrees.

Instructions :

Moisture of chemical products is very low in general,such as ammonium chloride (1%),products purple(4%)have drying process in the production .

Traditional crafts often use steam-heated drying,long production cycle,dried quality is poor,such as copper sulfate,although centrifugal dewatering,but there is still a small amount of absorbed water stained ,in order to dehumidify these stained water ,while heating using steam ,must evaporate absorbed water and copper sulfate materials,require more heat to complete the drying task.

Microwave heating features:

1 Penetrating whole heating,microwave can penetrate material internal,heating inside and outside at the same time,the heating rate is very fast;

2 Selective heating,due to the different electrical characteristics of material media,water and material have different microwave absorption capacity,microwave is preferred role to the materials that have strong absorption ability.

Use microwave heating characteristics,not only can shorten the production cycle,improve product quality,save energy(efficient),but also can improve the working environment,there is no dust pollution.Therefore, chemical products drying is playing advantages of microwave heating and drying technology.

Technical Parameters:

|

Model |

Rated input power(KVA) |

Microwave output power(KW) |

Expected dehydration(kg/h) |

Expected sterilization capacity(kg/h) |

Size L*W*H(mm) |

|

YM-10 |

14 |

10 |

8~10 |

50~80 |

5850*820*1750 |

|

YM-12 |

16 |

12 |

10~12 |

60~120 |

7200*860*2050 |

|

YM-15 |

21 |

15 |

12~15 |

80~150 |

8300*860*2050 |

|

YM-20 |

28 |

20 |

16~20 |

100~160 |

9400*860*2050 |

|

YM-25 |

36 |

25 |

20~25 |

180~200 |

10500*860*2050 |

|

YM-30 |

42 |

30 |

25~30 |

150~220 |

10500*1440*1750 |

|

YM-40 |

56 |

40 |

35~40 |

250~300 |

10500*1440*1750 |

|

YM-50 |

70 |

50 |

45~50 |

360~450 |

11600*1440*1750 |

|

YM-60 |

84 |

60 |

55~60 |

500~600 |

12700*1440*1750 |

|

YM-70 |

98 |

70 |

65~70 |

700~800 |

13800*1440*1750 |

|

YM-80 |

112 |

80 |

75~85 |

900~1000 |

14900*1600*1750 |

|

YM-100 |

140 |

100 |

90~105 |

1200~1600 |

15200*1660*1750 |

|

YM-120 |

168 |

120 |

110~120 |

1600~2000 |

17100*1660*1750 |

|

TL-150 |

210 |

150 |

140~160 |

2000~2500 |

20400*1750*1750 |

|

NOTE: We can specially design the equipment according to your products’ features and special production requirements. |

|||||

WELCOME TO CONSULT AND ORDER !

Mob/Whatsapp: 0086-15762088130

Email: info@cnyemai.com

Payment Terms︰ T/T ; L/C